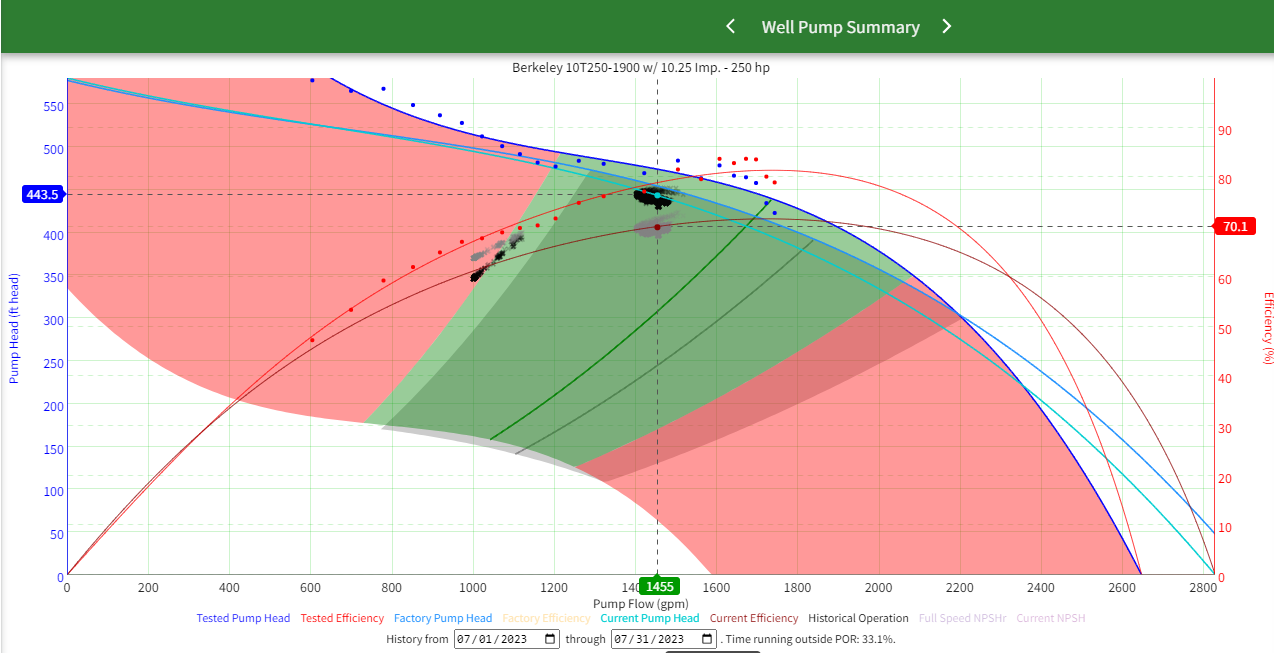

Aqua Water Supply Corporation is the second largest water supply corporation in Texas. Its service area covers approximately 1,200 square miles, delivering retail water to customers outside the greater Austin-area. The corporation uses water supplied from 41 production wells, including the S8 well site.

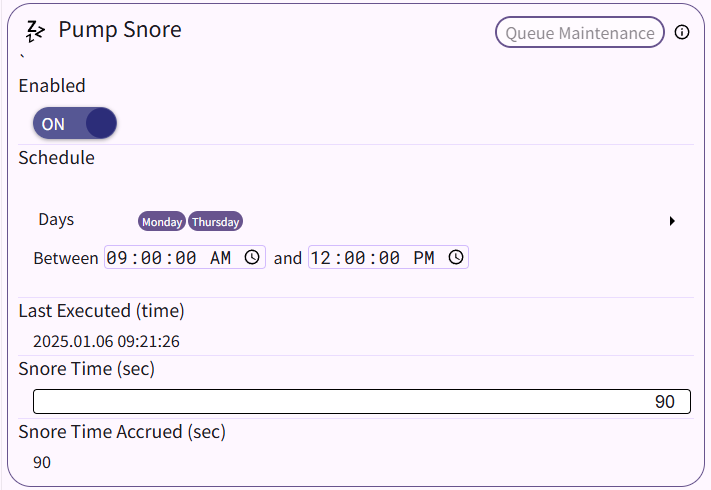

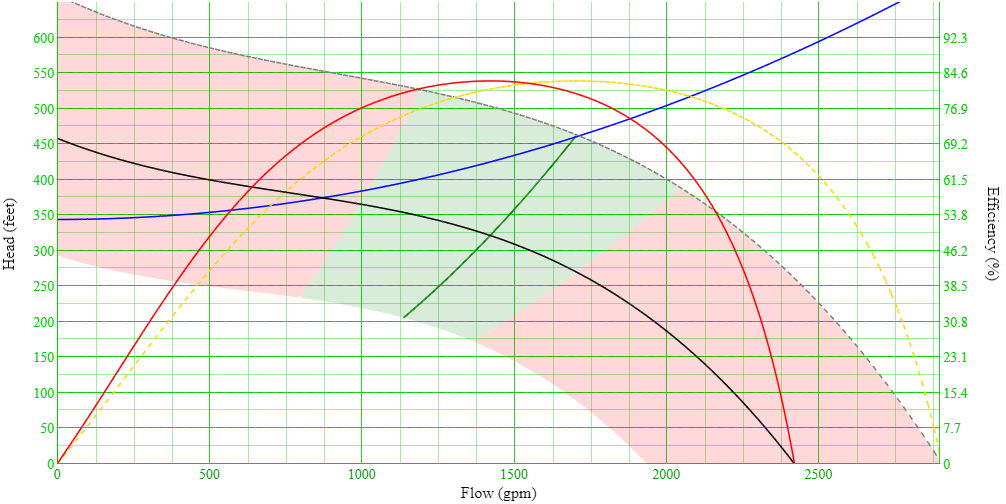

The S8 well produces up to 1,800 gallons per minute (gpm) from the Carrizo-Wilcox aquifer. The well is powered by a 250 HP submersible pump with a variable frequency drive...