DYNAMIC PUMP OPTIMIZER

powered by Tagger

SAVE TIME.

SAVE ENERGY.

SAVE YOUR PUMPS.

"Our real-time pump performance monitoring system is already paying dividends that translate to over $90,000 per year in reduced power costs. We also now have pump performance data to guide our pump rotation scheme." - Steven Seachrist P.E., Engineer V, Gwinnett County Dept. of Water Resources

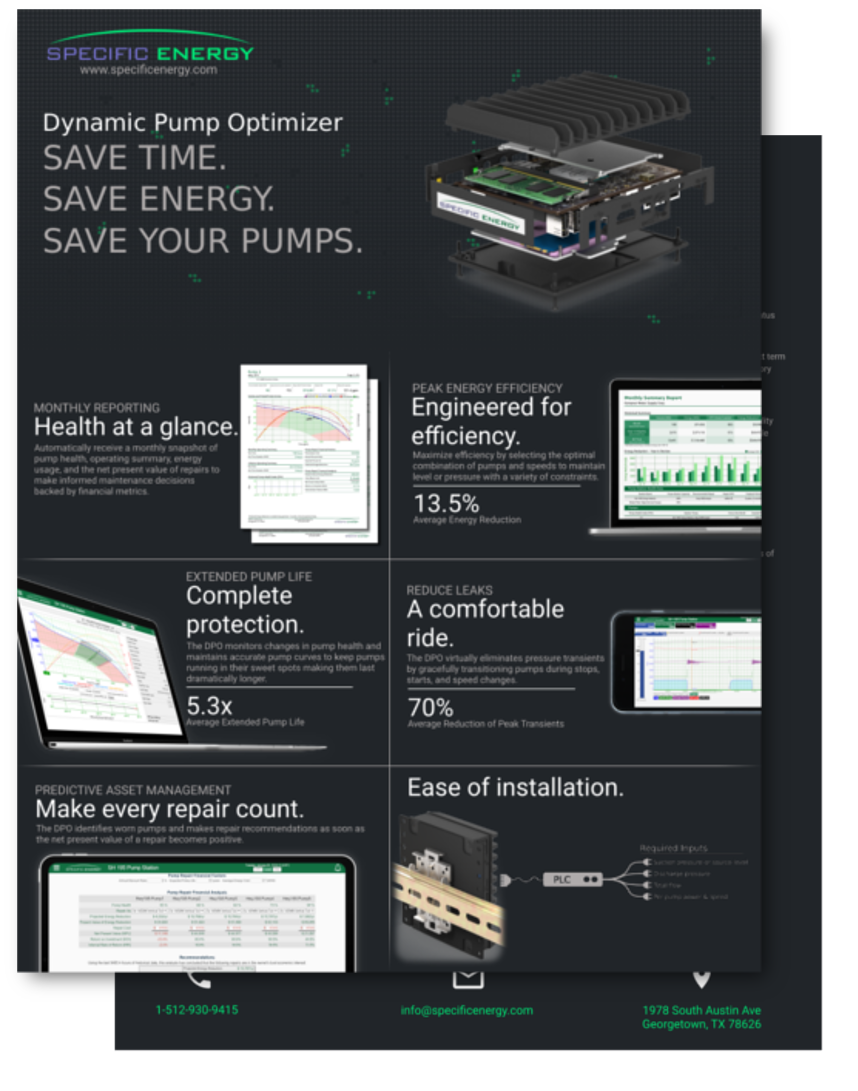

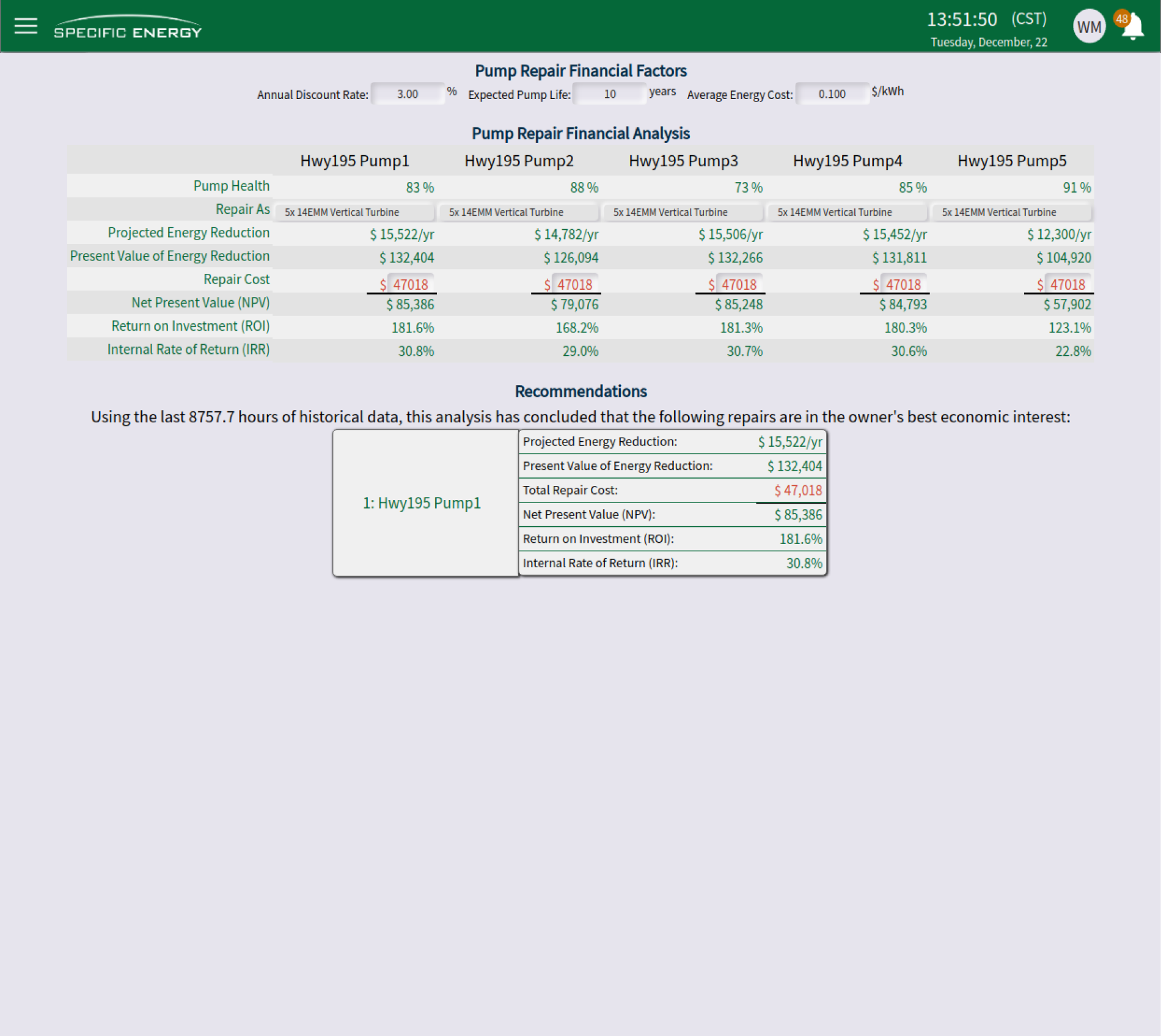

PREDICTIVE ASSET MANAGEMENT

Make every repair count.

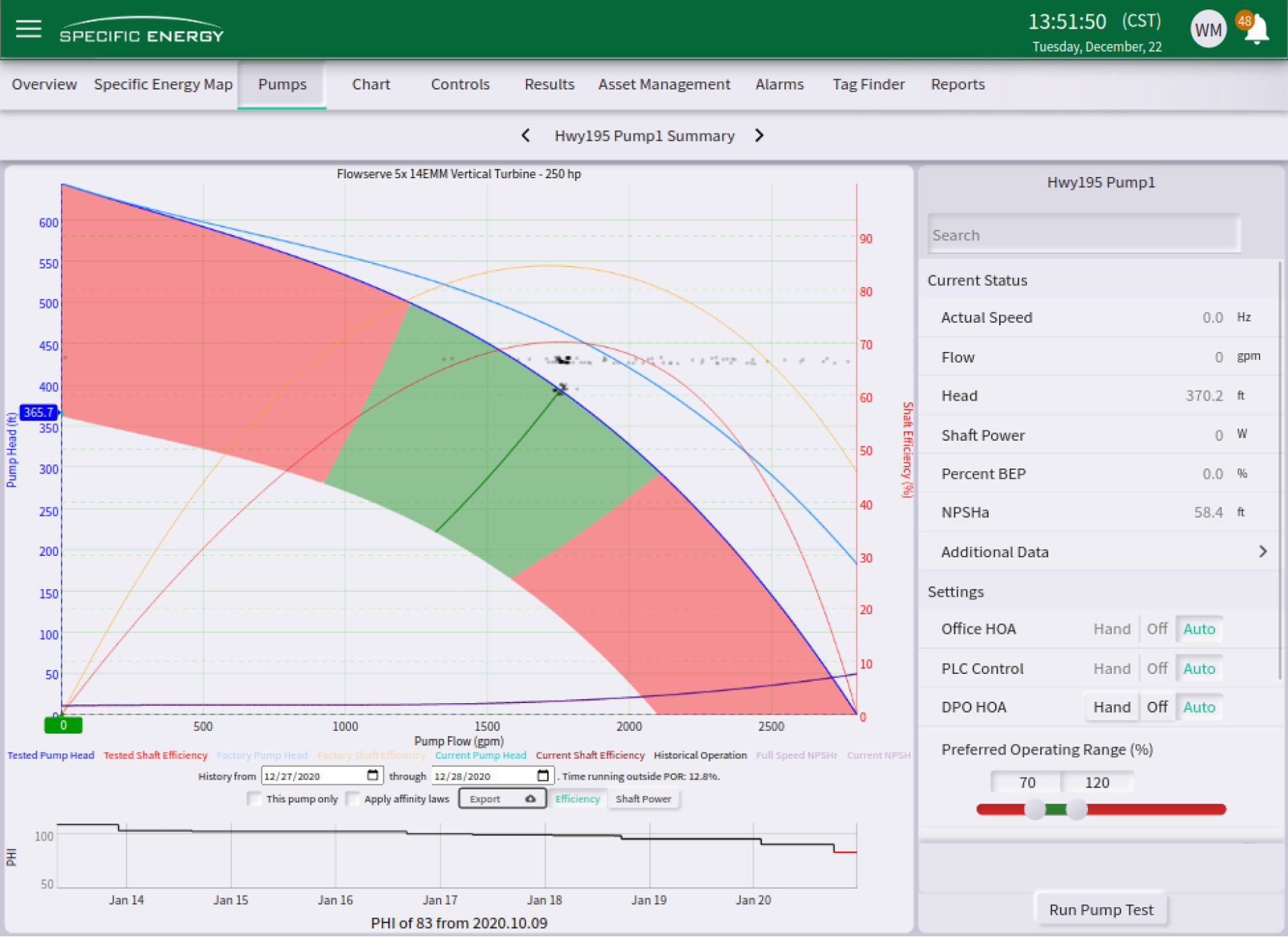

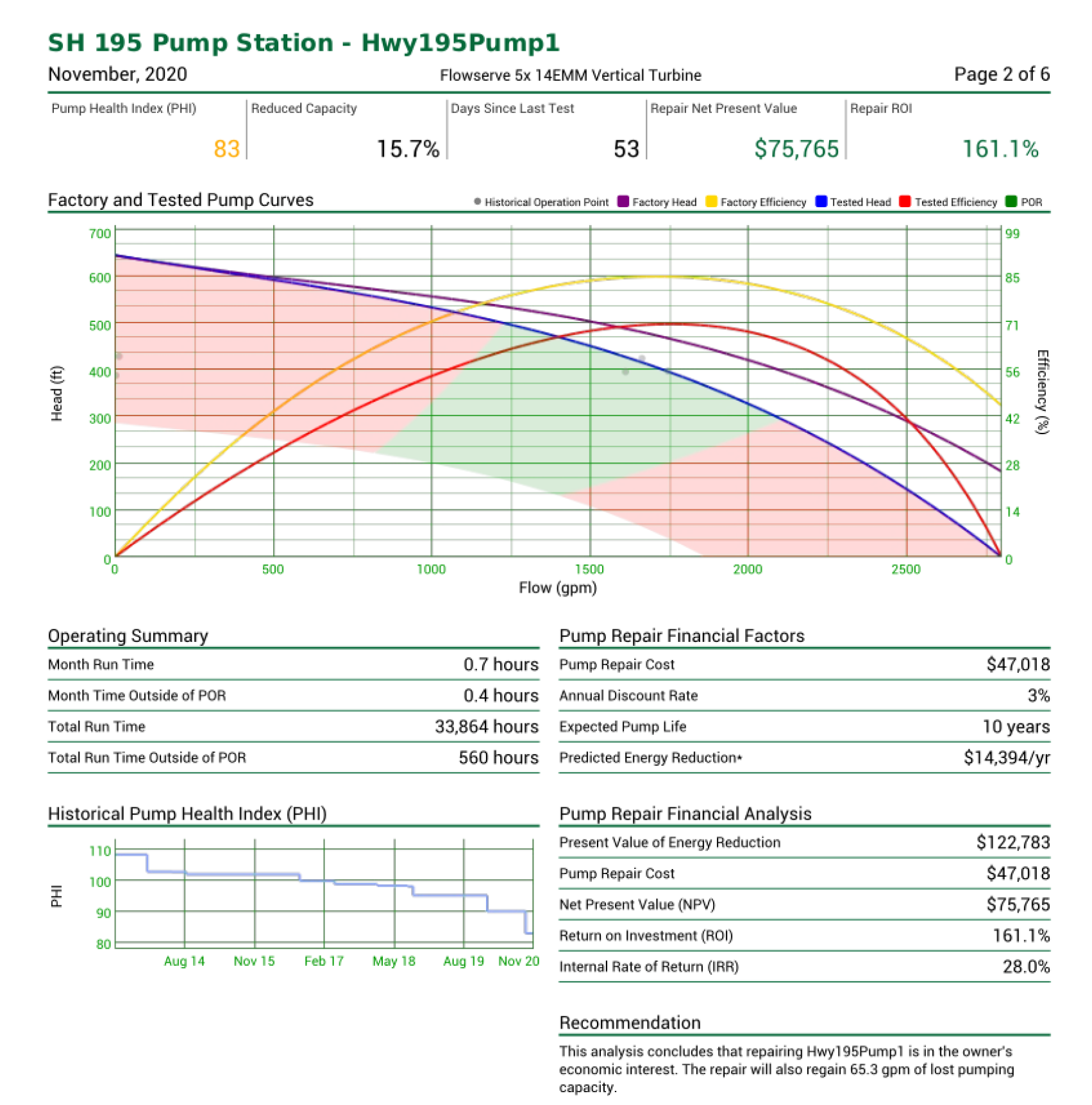

Reduce lifecycle costs and prevent unplanned outages with predictive asset management. The DPO identifies worn pumps and makes repair recommendations based on financial metrics instead of replacing pumps far beyond their useful life or even after complete failure. The DPO recommends repairs as soon as the net present value of a repair becomes positive.

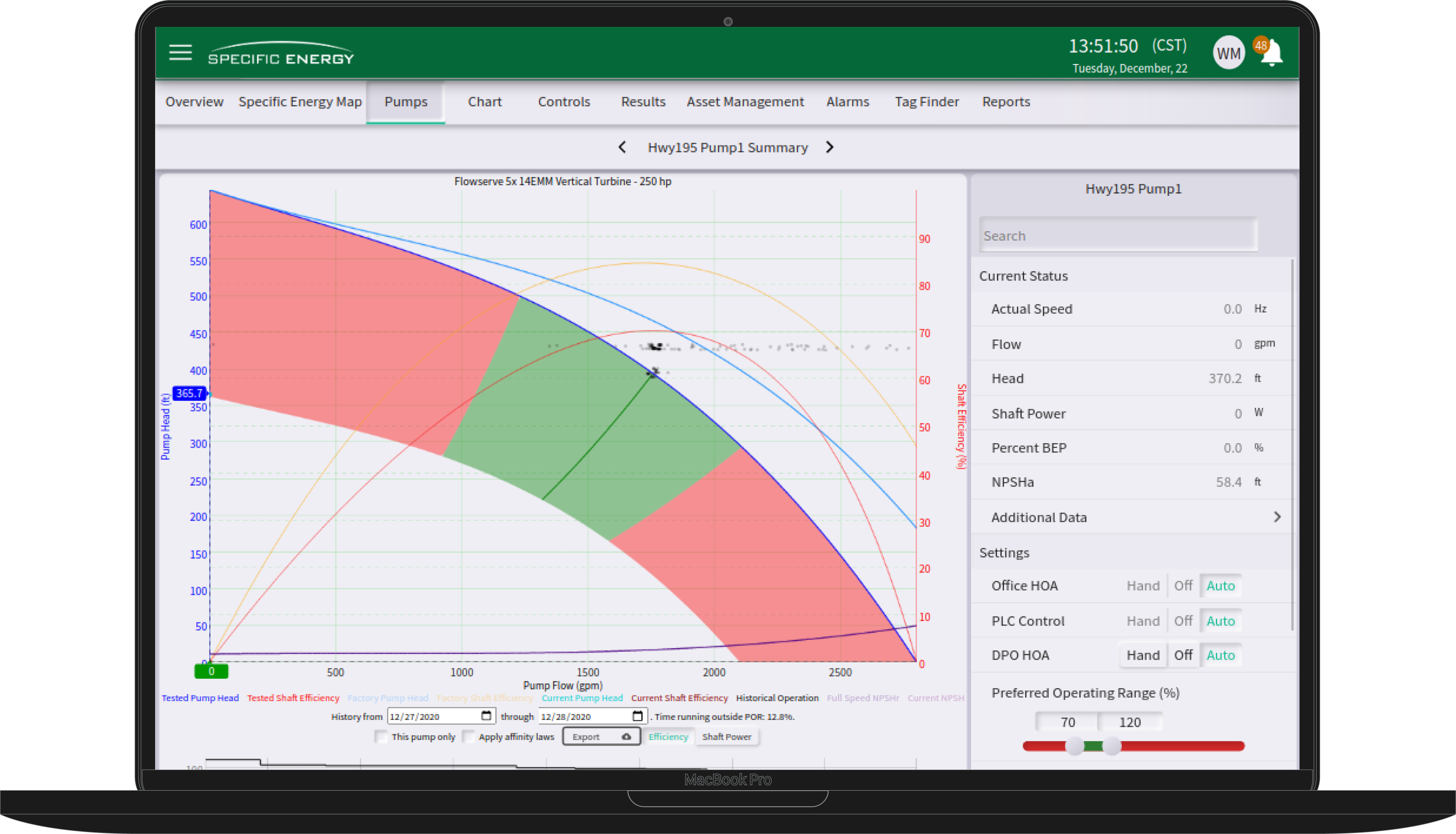

PEAK ENERGY EFFICIENCY

Engineered for efficiency.

Maximize efficiency by selecting the optimal combination of pumps and speeds to maintain level or pressure with a variety of constraints. Pumps run within their preferred operating ranges (POR) to minimize energy consumption without causing cavitation or other damaging effects.

13.5%

Average Energy Reduction

EXTENDED PUMP LIFE

Complete protection.

The Dynamic Pump Optimizer offers the best in pump protection to prevent pumps from cavitating, recirculating, vibrating, or experiencing other damaging effects of operating outside of preferred operating range. Pumps gradually wear causing them to become less efficient than factory condition and behave differently than PID loops would suggest. The DPO monitors changes in pump health and maintains accurate pump curves to keep pumps running in their sweet spots making them last dramatically longer.

5.3x

Average Extended Pump Life

REDUCE LEAKS

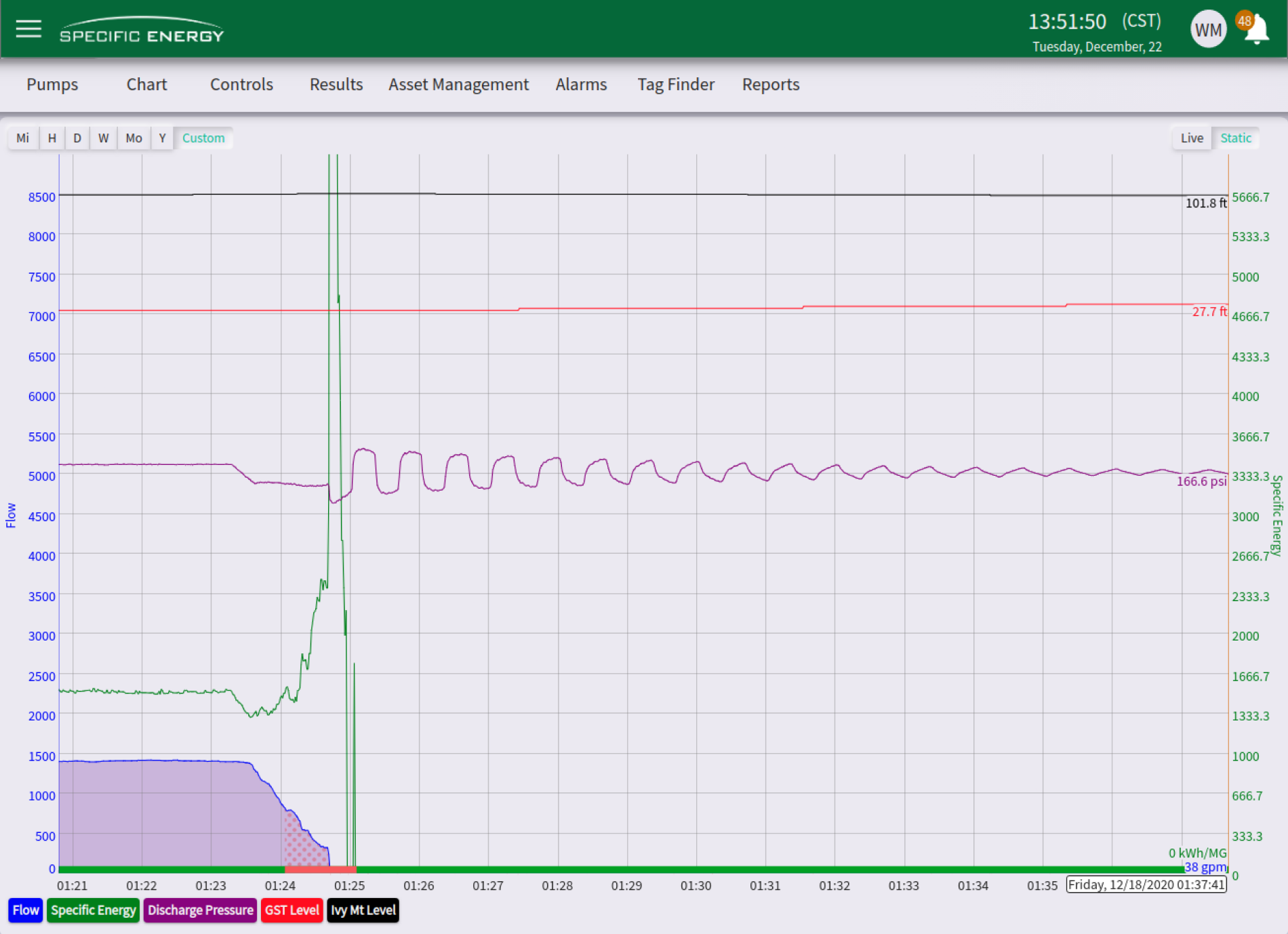

A comfortable ride.

Give pipes a comfortable ride with digital transient control. The DPO virtually eliminates pressure transients by gracefully transitioning pumps during stops, starts, and speed changes. Transient events can set up violent pressure waves that wreak havoc on a water system. The DPO minimizes pressure waves to reduce the frequency of line breaks.

70%

Average Reduction of Peak Transients

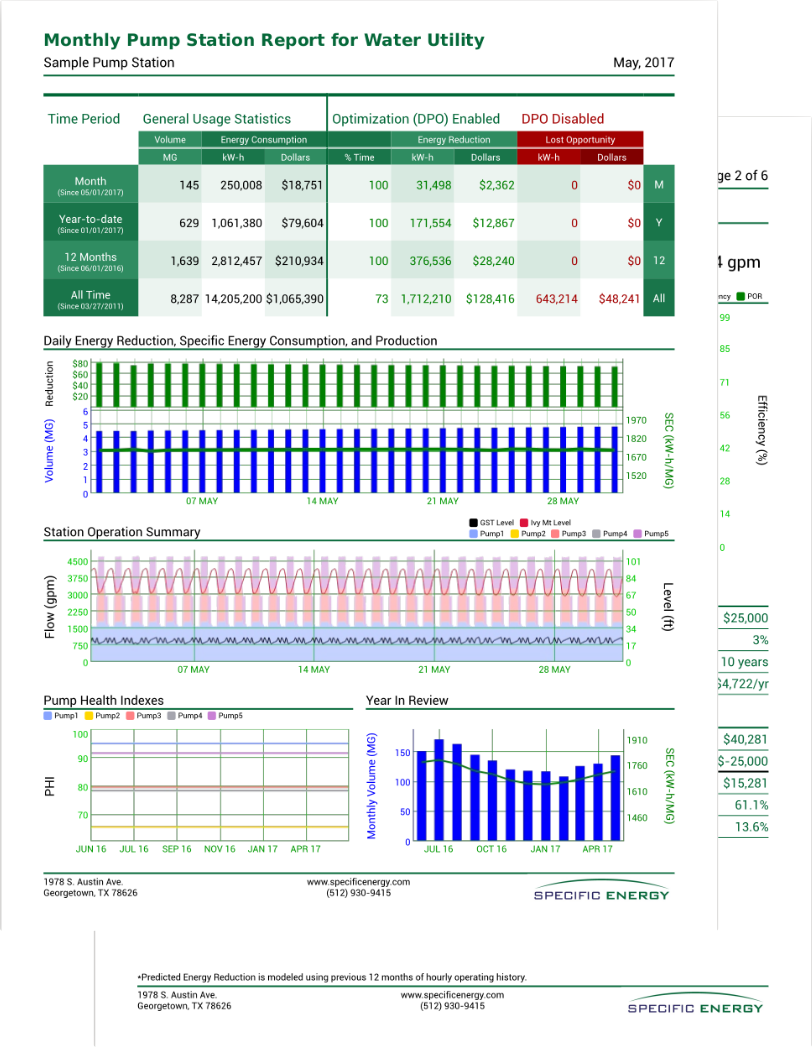

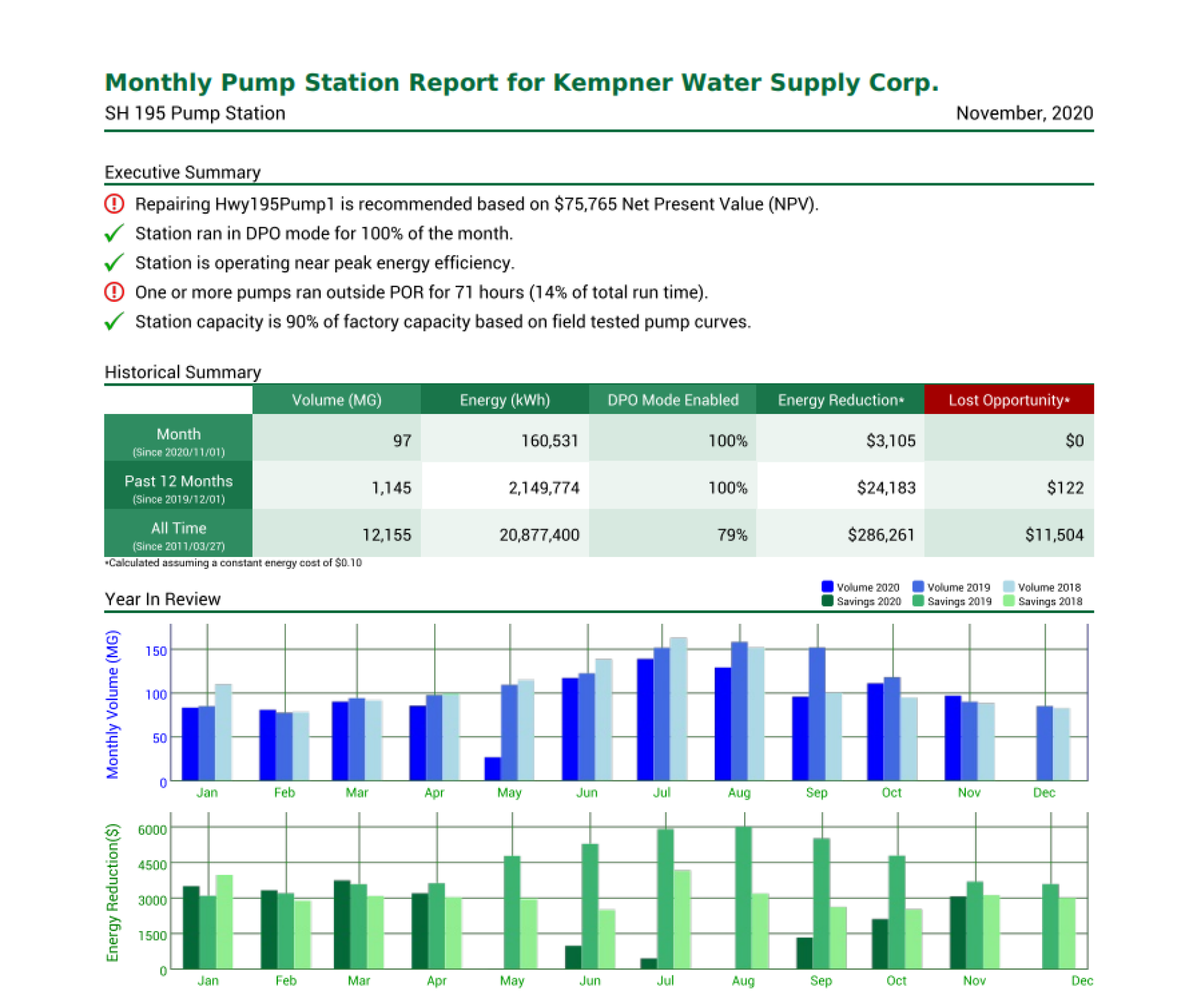

MONTHLY REPORTING

Station health at a glance.

Automatically receive a monthly snapshot of pump health, operating summary, energy usage, and the net present value of repairs to make informed maintenance decisions backed by financial metrics.

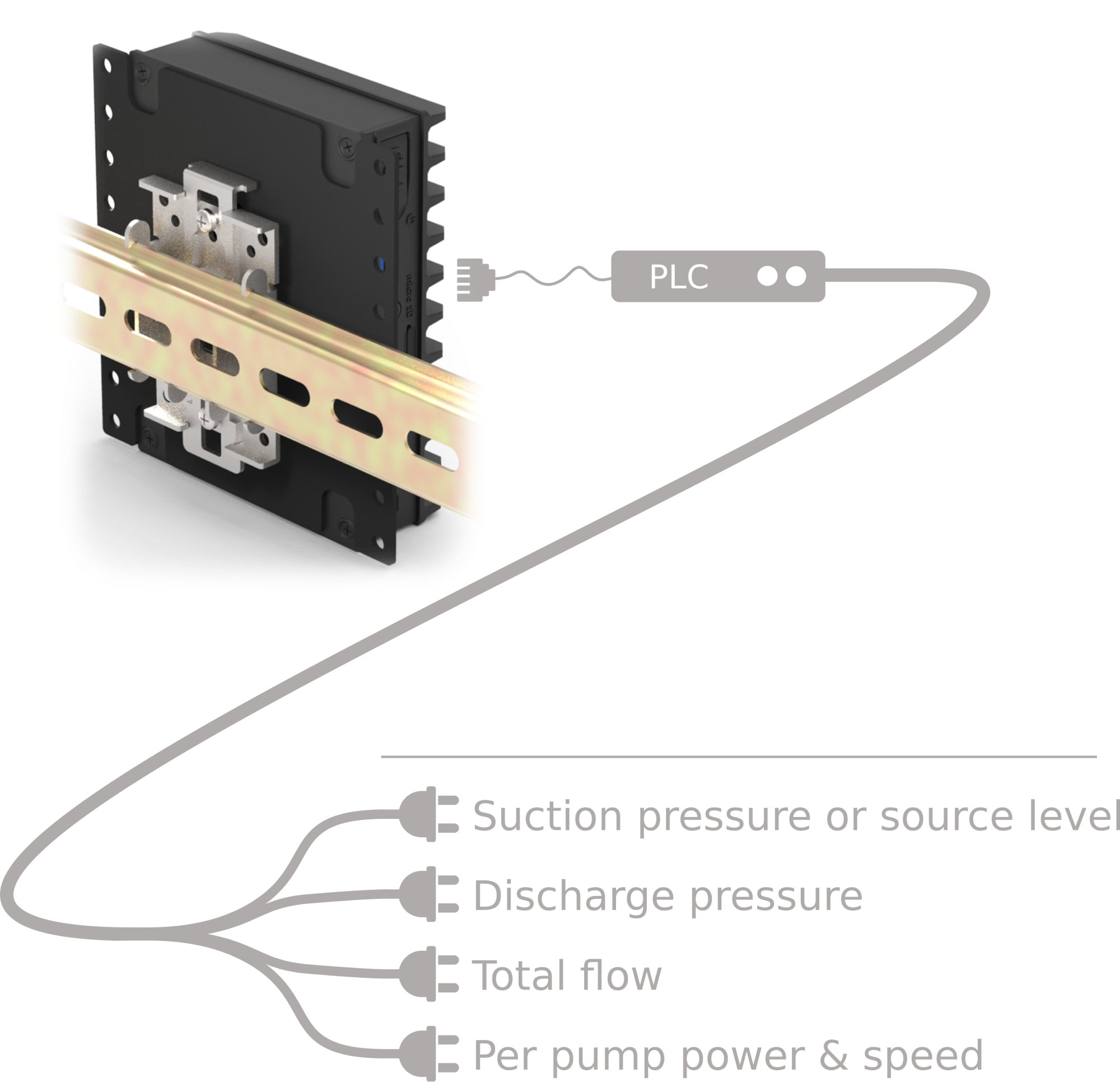

RAPID COMMISSIONS

Ease of installation.

The DPO communicates with an existing PLC to collect high resolution data. During an initial phase, the DPO monitors current pump station operation to establish a baseline for estimating energy savings and to perform pump tests. After a baseline has been established, the secure web based interface can be accessed to monitor, control, optimize, and perform asset management.